We support prototyping as a research and development partner.

Contact us for processing work that other companies cannot perform.

Feel free to contact us if you have any of the problems shown below:

We have experience and work achievements in a wide variety of fields, such as automobiles, semiconductor manufacturing equipment, medical devices, aviation, space equipment, energy, and industrial equipment.

We have experience in machining a variety of special steels (such as tool steels, a variety of mold materials, alloy steels, magnetic materials, stainless steels, and heat-resistant steels) and accumulated processing know-how according to material types. In addition, we have a procurement network for special steels to procure materials suitable for applications and shapes.

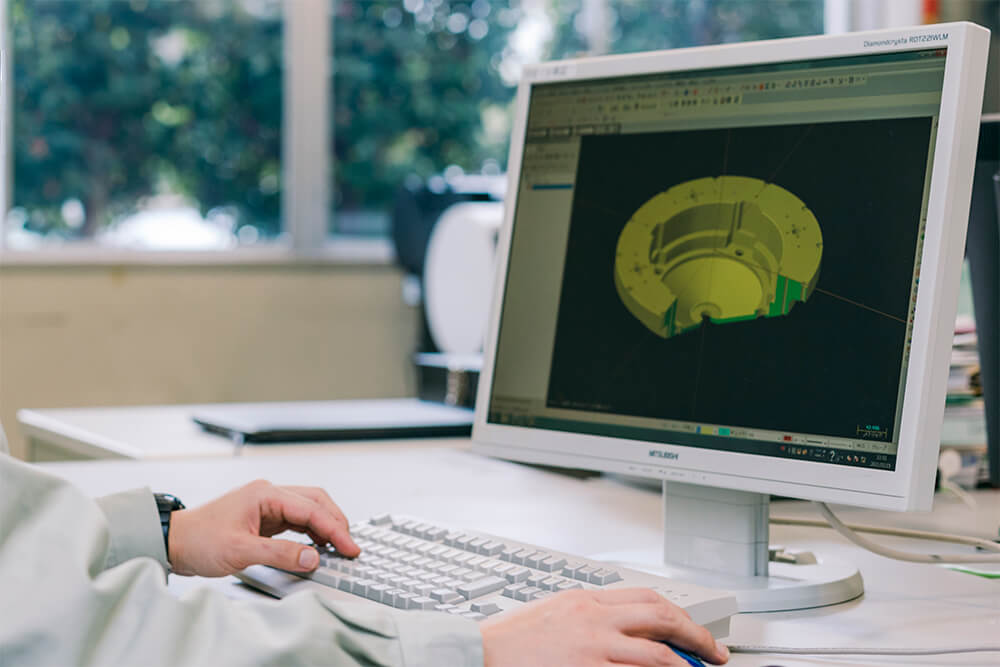

Because we have a wide variety of processing machines for jointing, vacuum furnaces, machining centers, lathes, surface grinding machines, and cylindrical grinding machines, we can create prototypes in various sizes ranging from the ones as small as a fingertip to ones as large as 7 m according to customer needs

We achieve reductions in lead time through an integrated production system that allows us to perform material procurement, cutting, heat treatment, precision finishing, and inspection in house.

To control quality consistently from materials to the finishing of processed products, we obtained quality management certifications of ISO 9001 and 14001, as well as IATF 16949 for vehicle-mounted vanes and AS 9100 for products for the aerospace industry. We can also assure dimensional accuracy using three-dimensional measuring devices and non-contact measuring instruments, perform magnetic property tests for magnetic materials, and assure the external appearance through liquid penetrant tests (color checks).

For surface treatments of coating and plating that cannot be performed with our equipment, we can respond to customer needs through our network of specialized companies. Even if drawings are not available, we can develop prototypes by sketching product samples borrowed from customers. In the case of mass-produced vehicle-mounted vanes, we can prototype several tens to hundreds of vanes.

【Head Office/Plant】

113-1 Enoshima-cho-Yasugi-shi,

Shimane-ken, 692-0057 Japan

FAX:+81-854-23-1403

【Tokyo Sales Office】

JRE Shiba-2-Chome Daimon Building 3F3-3 Shiba 2-Chome,

Minato-ku, Tokyo 105-0014 Japan

FAX:+81-3-5765-7507