Precision Machining

We delivery the quality that meets customer requirements by applying our processing technologies and know-how that we accumulated in handling special steel, Yasugi specialty steel, to high-accuracy finish of difficult-to-cut materials.

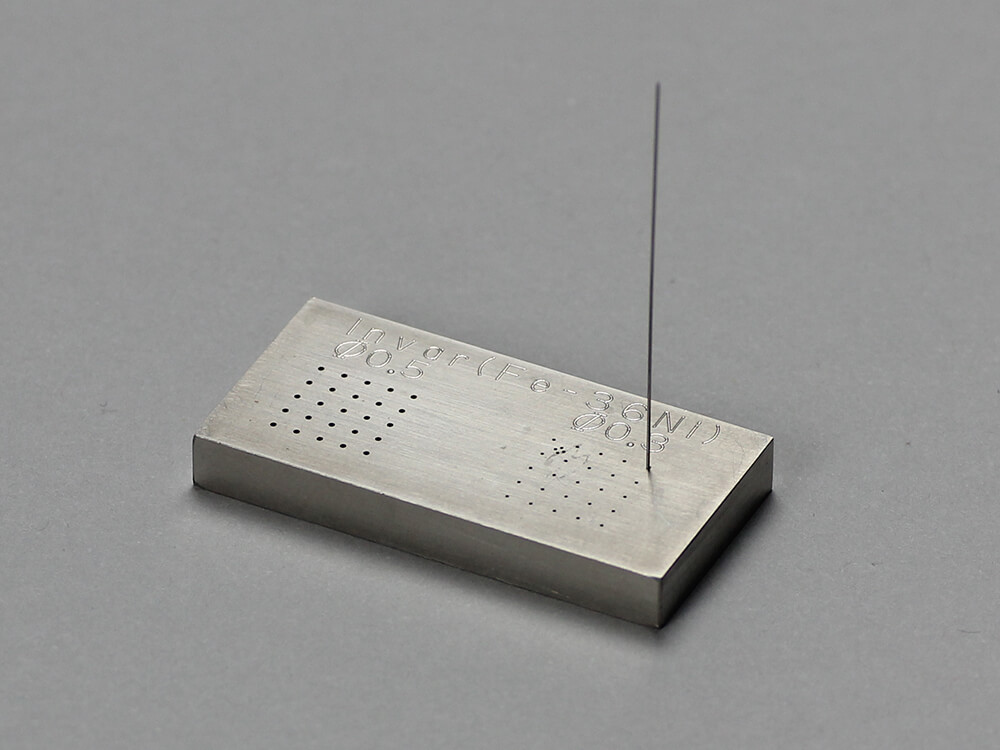

Invar

InvarIn the fields of aviation and space-related parts, semiconductor manufacturing equipment, and medical devices, the need for high-accuracy finishing of fine holes is increasing. We have achieved processing of deep, small-diameter holes with large aspect ratios (a processing depth relative to tool diameter) even in difficult-to-cut materials, such as Inconel and titanium.

The problems in processing are that cutting tools are likely to break during processing because the materials are difficult to cut, the tools have small diameters, and the cutting resistance is likely to be high because chips are generated and the tools wear significantly during cutting. Furthermore, work hardening is likely to occur depending on the material type. Therefore, it is necessary not only to select suitable processing tools but also to pay attention to the processing conditions (such as cutting, feeding speed, and step) and the way of applying cutting fluids according to the material type and processing difficulty. In addition, we are also working on the improvement of processing tools jointly with tool and coating agent manufacturers.

Among stainless steels, SUS630 (H900) precipitation hardened stainless steel, which is used for aircraft parts, shafts, and steel belts, is said to be particularly difficult to process. We have an established high-precision cylindrical finishing technology for shafts made of SUS630 (H900).

Because we have angular type cylindrical grinding machines, we can grind cylindrical and stepped parts as well as end faces. In cylindrical grinding, dimension accuracy, surface roughness, roundness, cylindricity, coaxiality, squareness, and deflection accuracy are required. As the warm-up of machines and variations in environmental temperatures affect accuracy, we pay attention to the air and cutting fluid temperatures during processing. We process approximately 300 various types of precision shafts a month and deliver quality and accuracy that are always stable.

【Head Office/Plant】

113-1 Enoshima-cho-Yasugi-shi,

Shimane-ken, 692-0057 Japan

FAX:+81-854-23-1403

【Tokyo Sales Office】

JRE Shiba-2-Chome Daimon Building 3F3-3 Shiba 2-Chome,

Minato-ku, Tokyo 105-0014 Japan

FAX:+81-3-5765-7507